Stage Series LED Lightbars deliver serious output and durability in a completely redesigned package. Designed for maximum functionality, both options feature high-intensity LED chips, custom-engineered TIR (Total Internal Reflection) optics, and powder-coated aluminum construction built to handle the elements.

All LED Lightbars are available in 6000k cool white, 3000k selective yellow output, or dual-color and include a distinctive backlight for a unique, modern look. With their versatile beam patterns, multiple functions, and easy installation, they’re perfect for roof racks, bumpers, and more.

The following installation guide provides general instructions for mounting the new Stage Series LED Lightbars on your vehicle. Keep reading for details.

Table of Contents

Tools Needed

- 10mm socket or wrench for lightbar mounting screws

- 1/2-inch socket or wrench for mounting hardware

Dimensions

SS6

SS10

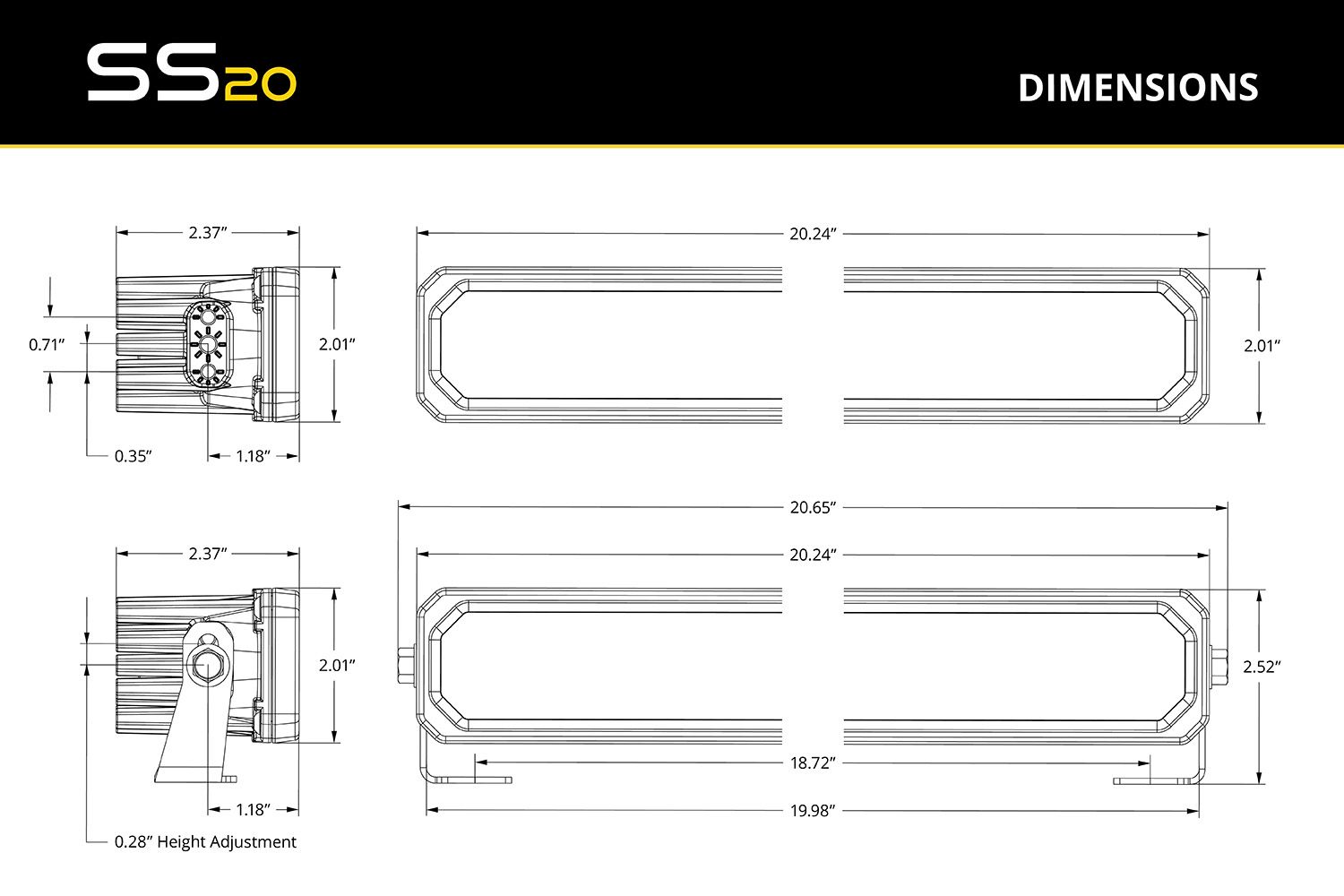

SS20

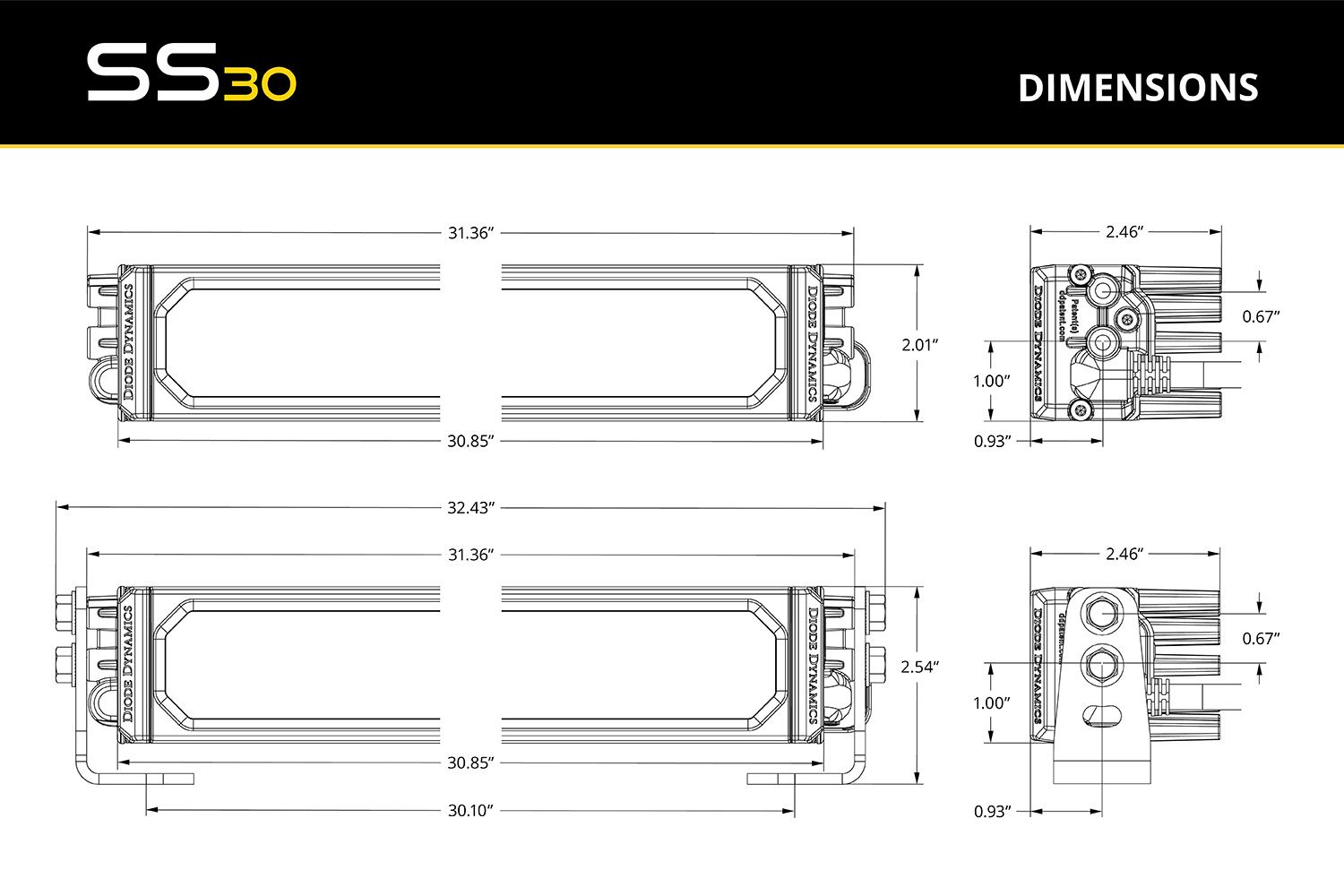

SS30

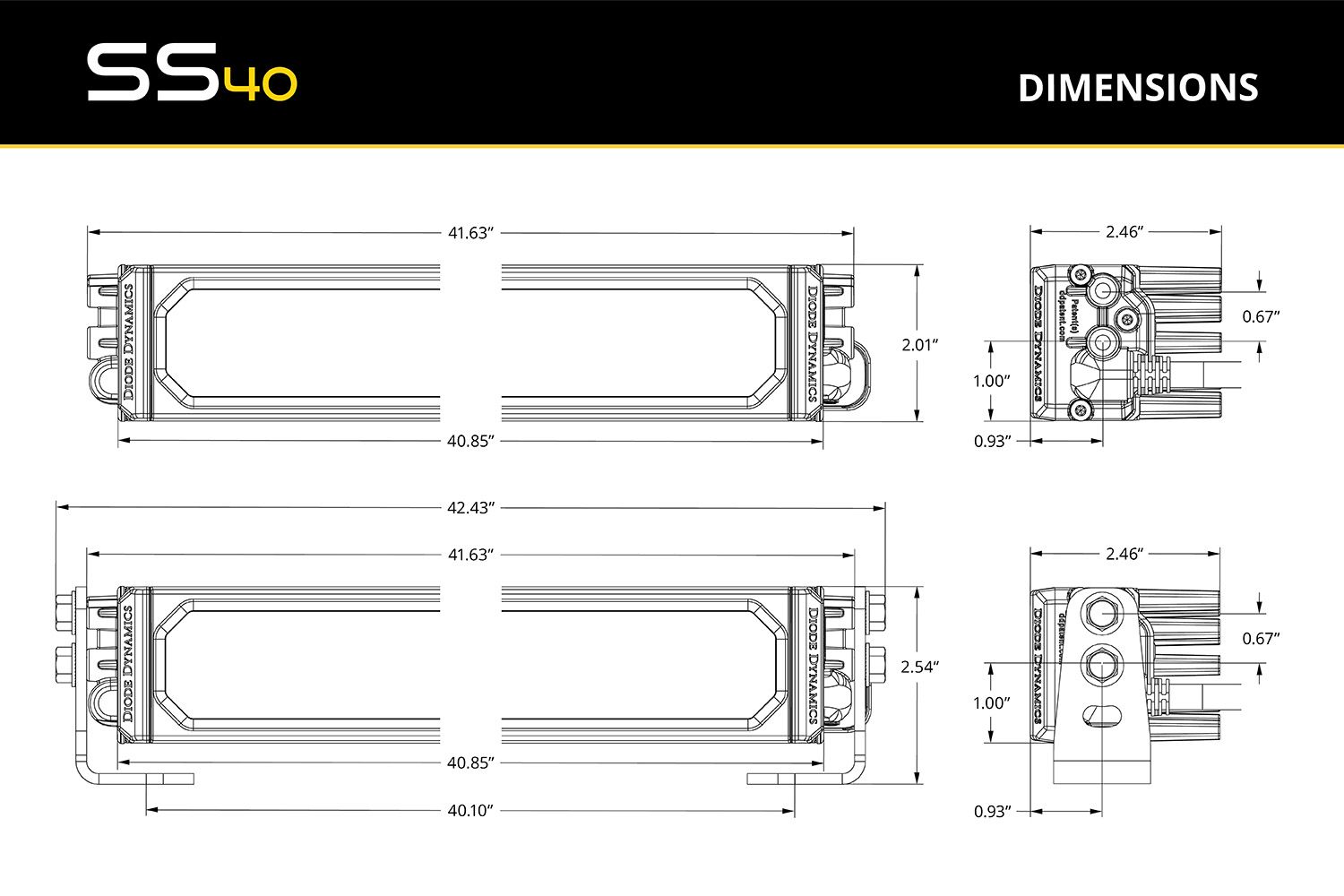

SS40

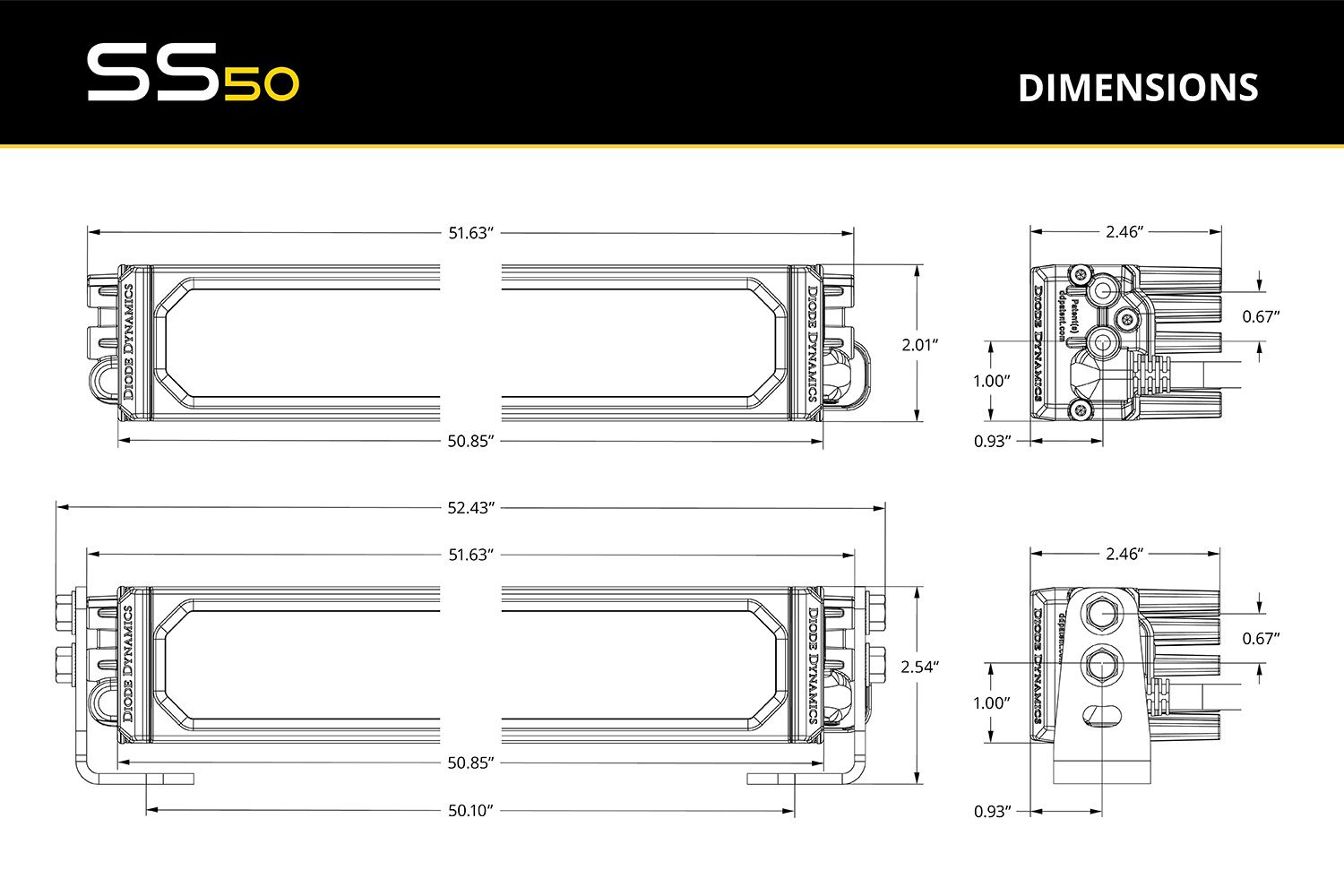

SS50

Mounting Instructions

Standard L Bracket Setup (SS6, SS10, SS20)

The standard mounting method for SS6, SS10, and SS20 Stage Series Lightbars uses two L brackets, one on each side of the lightbar. This setup allows for vertical adjustment before final tightening.

Note: The SS6 and SS10 lightbars are also compatible with the optional U-bracket and flush-mount kits (SS6 Only). These mounting options are sold separately and are not covered in this section.

Step 1: Attach the L Brackets to the Lightbar

-

Locate the two L brackets and identify the left and right sides.

-

Align one L bracket with the threaded mounting hole on the side of the lightbar housing.

-

Install one M6 flange screw through the bracket and into the lightbar housing.

-

Repeat for the opposite side.

Leave both screws slightly loose so the lightbar can rotate for aiming.

Step 2: Install the Mounting Hardware on the Brackets

Each L bracket uses one mounting bolt to secure it to the vehicle.

For each bracket:

-

Insert the carriage bolt downward through the slotted hole in the L bracket.

-

Place a flat washer onto the carriage bolt below the bracket.

-

Add the split lock washer.

-

Thread the hex nut onto the carriage bolt.

Do not fully tighten the hardware at this stage. The bracket should remain adjustable.

Step 3: Mount the Lightbar to the Vehicle

-

Position the lightbar and bracket assembly onto the desired mounting surface.

-

Pass the carriage bolts through the mounting surface or mounting accessory.

-

Center the lightbar and verify clearance around the housing and wiring.

Snug the nuts just enough to hold the lightbar in place while still allowing adjustment.

Step 4: Aim the Lightbar

-

Rotate the lightbar within the L brackets to set the desired vertical beam angle.

-

Slide the brackets as needed to fine tune left to right positioning.

Final aiming should be done with the vehicle on level ground.

Step 5: Final Tightening

-

Tighten the M6 screws securing the L brackets to the lightbar housing.

-

Fully tighten the nuts securing the brackets to the mounting surface.

Tighten hardware evenly on both sides to ensure proper alignment.

Tip

Perform final aiming at night with the lightbar powered on before fully tightening all hardware.

Standard L Bracket Setup (SS30, SS40, SS50)

SS30, SS40, and SS50 Stage Series Lightbars use a larger L bracket system designed to support the increased size and weight of these lightbars while still allowing vertical aiming adjustment before final tightening.

Step 1: Attach the L Brackets to the Lightbar

-

Locate the two L brackets and position one at each end of the lightbar housing.

-

Align the bracket with the threaded mounting holes on the side of the lightbar.

-

Install two M6 flange screws through the bracket and into the lightbar housing.

-

Repeat for the opposite side.

Leave all four screws slightly loose so the lightbar can rotate for aiming.

Step 2: Install the Mounting Hardware on the Brackets

Each L bracket uses one mounting bolt to secure it to the vehicle.

For each bracket:

-

Insert the carriage bolt downward through the slotted hole in the L bracket.

-

Place a flat washer onto the carriage bolt below the bracket.

-

Add the split lock washer.

-

Thread the hex nut onto the carriage bolt.

Do not fully tighten the hardware yet. The bracket should remain adjustable.

Step 3: Mount the Lightbar to the Vehicle

-

Position the lightbar and bracket assembly onto the desired mounting surface.

-

Pass the carriage bolts through the mounting surface or mounting accessory.

-

Center the lightbar and verify clearance around the housing, wiring, and cooling fins.

Snug the nuts enough to hold the lightbar in place while still allowing adjustment.

Step 4: Aim the Lightbar

-

Rotate the lightbar within the L brackets to set the desired vertical beam angle.

-

Adjust left-to-right positioning as needed using the bracket slots.

Final aiming should be performed with the vehicle on level ground.

Step 5: Final Tightening

-

Tighten the M6 screws securing the L brackets to the lightbar housing.

-

Fully tighten the nuts securing the brackets to the mounting surface.

Tighten hardware evenly on both sides to ensure proper alignment and support.

Tip

Due to the size of these lightbars, having a second person assist during aiming and tightening can make installation easier.

Wiring Instructions

SS6, SS10, and SS20 Stage Series LED Lightbars have an integrated Deutsch-style connector located on the back of the bar, just below the pin-fin heatsink, that securely fits the included Deutsch-style connectors.

The bigger Lightbars (SS30, SS40, & SS50) come with a DTP (Duetch Terminal Power) that are designed for high current applications with a wire lead coming directly out the side of the bar.

-

Determine a suitable location to mount the relay, near the battery or main power terminal.

-

Connect the red power input wire to the positive battery/power terminal. Connect the black ground wire to the negative battery terminal or a factory grounding point.

-

METHOD ONE - Add New Switch to Vehicle.

-

Determine a suitable location to mount the switch in the cabin of the vehicle. Route the switch wiring to that location. This may require

going through the vehicle firewall. We recommend following the path of the factory wiring harness, and unplugging the switch while routing the wires. -

Drill a 3/4 inch hole and mount the switch. Reconnect wires to switch, with the red wire in the center position

-

-

METHOD TWO - Use OEM Upfitter/Auxiliary Switches.

-

An extra wire pigtail is included with this harness, which should be used if you plan to control your lights with factory-installed

“OEM” switches. At the white connector, unplug the switch wires from the harness, and

connect the extra pigtail here instead. -

Using the butt connectors at the end of the pigtail, crimp the yellow wire and blue wire to OEM Auxiliary Switch wire leads. The yellow wire will

activate the main LED power, and the blue wire will activate the backlight LED power

NOTE: The main LED power will be drawn from the battery, so any OEM Auxiliary Switch wires can be used, regardless of amperage rating.

-

-

Route the output wire(s) to each LED, avoiding any moving parts or direct contact with heat sources. Plug the output connector into the LED.

-

Test thoroughly, and aim the LED appropriately based on use. Please check your local laws and regulations regarding aiming, installation, and restrictions for on-road use, as applicable.

Note: This auxiliary lamp draws high current and requires adequately-sized wiring for safe operation. If you are not using a Diode Dynamics wire harness, use a wire sized 16 AWG or larger for main power and ground. Use a wire sized 18 AWG or larger for the backlight (blue wire on the pigtail). Please be mindful of current ratings and wire size, especially if splitting power signals to multiple lights or using switches. If you have any questions, please feel free to contact us for assistance.

SmartSelect Programming

Stage Series Lightbars equipped with SmartSelect feature built-in programming for both the main beam and the backlight. Programming is performed using simple power cycles and works with any control method, including toggle switches, relay harnesses, or switch panels.

A built-in timing delay is included to prevent accidental programming from strobe functions or rapid switching. Each power cycle must be deliberate, with approximately one second between each ON press.

Main Beam Programming (SS30 and Larger SmartSelect Lightbars Only)

SmartSelect allows control over how the main beam operates. Depending on configuration, the lightbar can be set to run inner sections only, outer sections only, or the full bar.

-

Start with the main beam powered OFF.

-

Turn the main beam ON and OFF four times, spacing each ON press about one second apart.

-

On the fourth power cycle, the lightbar will enter programming mode.

-

Continue cycling power at the same steady pace to scroll through the available modes.

-

When the desired mode is displayed, leave the main beam ON.

-

After several seconds, the selection will save automatically and exit programming mode.

The selected mode will be retained during normal operation.

Backlight Color Programming

SmartSelect backlights offer multiple color options, including White (default), Red, Blue, Green, Purple, Yellow, Amber, and Teal.

-

Start with all backlight power OFF.

-

Cycle backlight power ON and OFF three times within three seconds, spacing each ON press about one second apart.

-

After the third cycle, the backlight will enter programming mode.

-

Continue cycling power at the same steady pace to scroll through the available colors.

-

When the desired color is displayed, leave the backlight ON.

-

After five seconds, the color will save automatically and exit programming mode.

-

Turn power OFF.

The selected color will appear any time backlight power is applied during normal operation.

Backlight Color Reset

If multiple SmartSelect products are connected to the same backlight circuit and colors become unsynchronized, perform the following reset procedure.

-

Enter backlight programming mode by cycling power ON and OFF three times, using the same one-second timing.

-

Continue cycling power through all available colors twice. This requires at least sixteen total power cycles.

-

After all colors have displayed twice, all connected lights will reset to White.

-

Leave the backlight ON for five seconds to save the reset.

-

Program the desired backlight color as outlined above if needed.

Questions About the Installation?

If you have any questions or issues installing the Stage Series Lightbars, please contact us for further information.

Where Can I Buy a Stage Series LED Lightbar?

If you're ready to upgrade your vehicle with Stage Series Lightbars, you can purchase them by clicking here, or by using our dealer locator to find a dealer near you.

Want to know more about Diode Dynamics products? Visit DiodeDynamics.com and subscribe to our newsletter for new product releases and more!

This Installation Guide is for the following SKUs: DD8180, DD8181, DD8182, DD8183, DD8184, DD8185, DD8186, DD8187, DD8188, DD8189, DD8190, DD8191, DD8192, DD8193, DD8194, DD8195, DD8196, DD8197, DD8198, DD8199, DD8200, DD8201, DD8202, DD8203, DD8204, DD8205, DD8206, DD8207, DD8208, DD8209, DD8210, DD8211, DD8212, DD8213, DD8214, DD8215, DD8216, DD8217, DD8218, DD8219, DD8220, DD8221, DD8222, DD8223, DD8224, DD8225, DD8226, DD8227, DD8228, DD8229, DD8230, DD8231, DD8232, DD8233, DD8234, DD8235, DD8236, DD8237, DD8238, DD8239, DD8252, DD8253, DD8254, DD8255, DD8256, DD8257, DD8258, DD8259, DD8260, DD8261, DD8262, DD8263, DD8264, DD8265, DD8266, DD8267, DD8268, DD8269, DD8270, DD8271, DD8272, DD8273, DD8274, DD8275, DD8375, DD8377, DD8378, DD8379, DD8380, DD8381, DD8382, DD8383, DD8385, DD8386, DD8387, DD8388, DD8389, DD8390, DD8391, DD8392, DD8393, DD8394, DD8395, DD8396, DD8397, DD8399, DD8400, DD8401, DD8402, DD8403, DD8404, DD8405, DD8406, DD8407, DD8408, DD8409, DD8410, DD8411, DD8413, DD8414, DD8415, DD8416, DD8417, DD8418, DD8419, DD8420, DD8421, DD8422, DD8423, DD8424, DD8425, DD8427, DD8428, DD8429, DD8430, DD8431, DD8432, DD8433, DD7781, DD7782, DD7783, DD7784, DD7785, DD7786, DD7787, DD7788, DD8644, DD8645, DD8646, DD8647, DD8648, DD8649, DD8650, DD8651, DD8652, DD8653, DD8654, DD8655, DD8657, DD8659S, DD8781, DD8801, DD8815

Share This Post